Whilst the major OEM’s are lobbying hard to mitigate the consequences, the finished vehicle logistics industry needs to prepare for potential bumps in the road. We don’t know for sure, but we can surmise that we will face some challenges:

- Import tariffs

- Customs delays

- Labour shortages

What we do have is a little time before the UK exits and the ability to create changes within the supply chain to make processes more cost efficient as well as operationally effective. Improving the position now, means less pain in two years’ time.

Using digitalisation to power the supply chain

So what is digitalisation and how could it help? The art of digitalisation is the application of technology and information to improve the service. Uber is a great example. The taxi remains largely the same, but clever technology alerts drivers to service requesters and guides them to the correct location. It tracks the journey to ensure that the route is a fair one and finally removes the need to carry cash – the fare is debited directly from the user’s bank account. Everyone wins, particularly Uber and their drivers; they are not competing on price (though they are competitive), so they are not cutting into their profits all the time. They actually charge more when it gets busy, but people still choose to use Uber.

What digitalisation should not be is a solution hunting for a problem, for example RFID. Though valuable as part of a connected system, they won’t achieve much on their own.

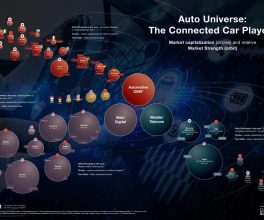

So how about the finished vehicle logistics chain? The “noise” in the sector suggests that we are at the point of change. We saw at the ECG Conference in Hamburg in 2016 discussion about how the outbound industry is being left behind in a world that is turning more and more towards digital technology and e-commerce. Finished Vehicle Logistics magazine has been reporting on ‘Brexit and smarter use of data dominate’; looking at how the market is creating efficiencies in the supply chain through smart logistics solutions at ports and compounds as well as improving transport communications and optimising the supply chain. Finally, the ECG is already hosting quarterly Working Groups focused on digitalisation. With the most recent meeting in Brussels involving both OEMs and LSPs, there was substantial interest in aspects such as supply chain visibility, driver management systems, mobile communications, RFID and other tracking technologies to aid transport flow, the possibility of a secure platform for data exchange and in-vehicle technology such as telematics to improve distribution.

But what can we actually do as an industry that embraces the changes that Uber brought to Taxis? The agenda has to start with the customer:

- Where are my cars (They are an asset and we ought to know)?

- How is my flow (will I meet my quarterly targets)?

- What’s the ETA (please someone tell the end customer what is going on)?

- Prioritise sold vehicles (we can get paid quicker and boost profits)

- Cut delays by joining up the logistics chain (shorter chains cost less)

Call these the five signs of success. It’s a simple list but no one can say yes, my logistics chain exhibits all these traits.

Smart systems start with Business Intelligence

Underlying a smart digitised logistics system is information. Gathering it needn’t be an overhead. The trick is to interact, system to system with each 3pl in real time preferably. Suddenly you know where every vehicle is and can tell the dealer/customer. The estimated time of arrival is easy to calculate.

Next is optimising the flow. That’s easy, it’s just regulating the movement of cars between each node. Any system will only deliver as many cars as the lowest capacity part (also known as the bottleneck). Everyone should know their bottleneck and work to ensure that it can deliver next quarter’s target.

So, before exploring what technology and software to purchase, the starting point is to understand the part (or all) of the supply chain to be addressed – identify what processes need enhancing, build key assumptions around the process and define any key blockers that have already been detected. Committing budget to IT investment is significant for any importer, so understanding the functional and strategic requirements from an investment first is vital.

Only once you have identified these requirements, is it time to test the market and find a solution that meets your needs rather than you fitting into an IT system!

Making sure the IT investment works for you

The move to a digital world isn’t about having the latest IT, it’s about using technology to drive the five signs of success. These should not cost more money, they save it. Every car in the logistics chain costs at least 40p per day in interest – even if its parked for free (nothing is free, the real cost is nearer £4 per day). Save time, save money. Get the flow going; cut dwell times at compounds, don’t wait for a car to be in stock before you plan the next stage.

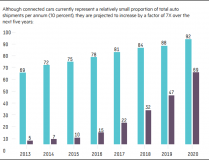

The savings through digitalisation are 5:1. Invest £1, save £5. With one eye on Brexit, surely that sounds pretty attractive.

Automotive industry supply chain and logistics expert John Miller-Wilson

Courtesy of Sovereign Business Integration Group Plc