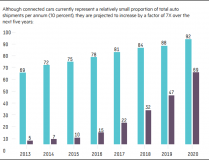

Off-late, it has become almost unavoidable when we can completely avoid the discussions happening around partially or completely autonomous cars. These cars are usually driven via AI technology using the data collected from the ecosystem. The automotive critics and experts have similar thoughts on the benefits, shortcomings, and future of significant innovations that’ll disrupt the automotive industry.

As reported by Statista-

- The European passenger car market is estimated that the unit sales volumes will reach 15,531.63K vehicles in 2027.

- The passenger car market’s revenue would reach $413.50 bn in 2023; by 2027, it would generate revenue amounting to US$ 452.20 bn. During the forecasted period, the growth CAGR remains at 2.26%.

With all these stats complemented by the advancement of technology, it is clear that automotive companies are likely to benefit from the transformations and disruptions that AI and Big Data will bring to the table for next-gen cars. Despite all this growth, to get into the reality of the technological expectations, it would need at least a quarter of the automotive manufacturing and supplier staff to become AI-savvy in the coming decades. This continues to be a challenge for the automotive industry, which is indeed a challenge for the industry related to the upskilling of their employees.

Going Back in History – Remembering Major Auto Recalls

Vehicle recalls time and again made the headlines, causing car manufacturers to suffer losses worth millions of dollars and a dent in their well-established reputations. This is because the automotive industry is amongst the ones where the manufacturing processes are quite strict regarding quality checks, timely maintenance, and monitoring.

- In the year 2014, over 64 million units of cars were forced to be taken off the market, marking one of the worst years for the automotive industry in terms of the number of vehicles recalled.

- 3 years later, in 2017, though this number witnessed a major drop, recording 10 million recalls, there was no prominent reason for the automobile manufacturers to celebrate.

- In March 2018, Tesla recalled a major portion of its Model S fleet of 120K Cars because of faulty steering components. This recall caused a sharp fall of over 4% in Tesla’s share prices after announcing the vehicle recall.

As technology is transforming vehicles with the help of digital platforms and solutions, backed with security, efficiency, and increased computing power performance, the time has arrived when the manufacturers need to be smart while deploying the right technologies across all stages of the production and post-purchase lifecycle. This is where technologies like AI, Machine Learning, Big Data, and Predictive Analysis provide the manufacturers with complete visibility and control of the manufacturing process.

Changing Scenarios – From Mechanical Cars to Digital Cars

Although vehicles have always been perceived as completely mechanical, they’re certainly not immune from digital transformation, as we’re witnessing it through the growth of new technologies. The results are visible in AI, Machine Learning, and Big Data Analytics fields that have transformed the automotive industry.

For OEMs, digital enhancements have become an indispensable solution as they continuously invest in improving the quality of key parts like engines and chassis, emphasizing safety and productivity. Using digital technologies like AI and Big Data, OEMs are working towards improving the driving experience to address customer expectations, making them towards the designing and creation of Digital and Connected cars.

Role of AI & Automotive Industry

Automation has been an indispensable component of the automotive industry for years now, though it’s important to understand the differences between a standard automation tool and an AI application. Deploying automation at the automotive workplace is all about the involvement of technology with a predetermined route. For instance, machines can be programmed to undertake repetitive and mundane tasks over the assembly line. AI can be used to analyze data that continually adapts for higher efficiency and also predict future events.

With AI now being used to make accurate predictions and respond according to the changing scenario, the true capabilities of AI lie beyond what was previously achievable with only automation and applications for manufacturing, maintenance, and overall driving experience.

Big Data’s Significance in the Automotive Industry

In recent times, the term Big Data has emerged as a buzzword for different reasons, and its benefits reflect why. The term is used for denoting various data sets with variety and arrival at greater velocity and volumes compared to the past. These data sets are usually too big and complex to be used with traditional data processing techniques; they need advanced analytical systems and complicated algorithms for drawing inferences.

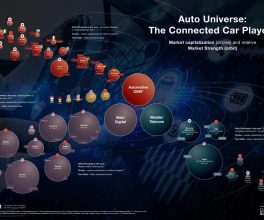

Talking about the role of Big Data in the automotive industry encompasses everything, from gathering data on consumer behavior and preferences to data on driving patterns, vehicle and riders’ locations, along with data from other cars on the road. Most AI-based applications heavily rely on Big Data, suggesting the indispensable need for automotive engineers to understand the importance of Data Analytics.

Automotive manufacturers can now safeguard themselves from serious issues by rapidly discovering mechanical and design problems after the manufacturers have developed the right procedures for collecting and using data. The data acquired by OEMs can be highly important and should be addressed. Collected data includes specifications and details on the parts’ conditions when vehicles are serviced and after an accident.

Manufacturers also use this data-driven design approach to increase the customers’ trust. Online research proves that a large volume of recalls does not hamper OEM sales but also the vehicles manufactured by their competitors in the same region. By highlighting the pain areas and rectifying them before mass recalls happen, OEMs can prove that their quality control is good enough to catch and resolve problems before they loom too much. It also increases brand trust among the target customers in the used and new car markets.

How AI & Big Data Helps in Reducing Recalls?

Present-day technologies like AI in the future will assist manufacturers in building improved and safer vehicles, thereby reducing the possibility of addressing recalls. By analyzing data gathered from various sources of the vehicle’s ecosystem and using Machine Learning, OEMs access this real-world data about how vehicles perform under specific driving circumstances, considering external factors like- weather’s impact, conditions of the road, drivers’ habits, wear and tear of parts, and all those components that impact the vehicle’s performance. Despite several challenges, OEMs need to take additional steps below to incorporate data into designing and developing vehicles.

The first step involves tapping into and using the Big Data collected by the sensors in the vehicles, especially with the rise of connected, autonomous, and semi-autonomous vehicles. This, together with the data collected by repair facilities concerning particularly physical and operational issues, weather, traffic, and the condition of the roads, thereby provides key insights into a vehicle’s performance. This would allow the manufacturers to understand better how to avoid issues that yield a recall, and they could use real-world data to help them design improved parts or upgrade the vehicle software. Eventually, automated production systems act on this data immediately to change the manufacturing process to improve products on the assembly line.

Most modern cars have advanced sensors to analyze the data collected in the car’s ecosystem. Intelligent AI systems are important in performing preventative analysis for several areas. The core benefit of using advanced analysis is that they can engage in machine learning, enhancing the knowledge of what makes the vehicle work and what prevents it from working to create a model that OEMs need to use to eliminate major problems.

Car manufacturers are now leveraging the Autolytic capabilities of the automotive technology solution provider companies like AutoFacets to ensure they can accurately predict the vehicle’s health and alert the drivers beforehand.

Concluding Words:

The benefits of AI and Big Data technologies are evident; hence, automotive manufacturers must gather and analyze the high-volume data sets and use the observations to boost AI-based applications to remain competitive. The present-day’s automotive engineers need to privately use Big Data and AI across all aspects of their operational areas or be at risk of becoming a laggard.