Recalling faulty products is difficult in any industry. The fallout can be horrific, and have serious implications for companies of all sizes – just look at the recent issues within the automotive industry. Hyundai-Kia and Ford have recently been forced to recall thousands of faulty vehicles due to safety concerns. Controls in the automotive industry are of the utmost importance, as the fallout goes further than financial and reputational damage – people can get hurt as a result of product failures.

What’s going on?

Some frightening news has been brought to light with recent research conducted by Auto Express. The research includes figures obtained from the Driver Vehicle Standards Agency (DVSA) that demonstrate the gloomy state of affairs for the automotive industry. Roughly 2.2 million vehicles were affected by recalls, with the top 10 list of recalls since 2012 led by Takata Corporation, an automotive parts company based in Japan, recently involved in a wide scale airbag recall.

In June this year, Ford was forced to recall more than 400,000 vehicles over safety issues, affecting vehicles that were built in the company’s Kansas City assembly plant. Problems included loss of motive power while driving, or unintended movement when the parking brake is applied, presenting obvious safety concerns for drivers.

Ford is not the only case. South Korea recently ordered Hyundai Motor Co and its affiliate Kia Motors Corp to recall over 240,000 vehicles due to defects in parking brake warning lights.

Introducing an extra layer of rigour to already rigorous quality control

When cars are stalling, it’s not just us as consumers who are demanding immediate answers. Manufacturers are also looking at themselves and asking how these product recalls can be avoided. They want to be the best and hold themselves to high standards. So when quality control issues escalate and harm their customers, it affects them greatly.

They already have stringent quality control processes in place before products are shipped. So what can be done to add an extra layer of rigour to already rigorous product testing?

AI and machine learning to the rescue

Imagine being able to predict something going wrong before it does, to pre-empt failures and proactively take corrective actions. This is where artificial intelligence and machine learning come into play.

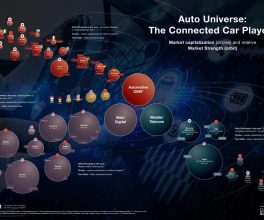

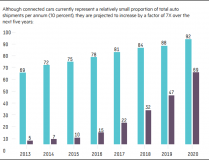

We’re entering the fourth industrial revolution in which smart and connected devices, powered by machine learning and AI, are able to predict faults and anomalies in the manufacturing process. With the recent explosion of data and the increasing volume of sensors on every day devices, these technologies that have been around for decades are now becoming a reality.

We now have the ability to create a full digital copy of an engine. This is achieved through the creation of ‘Digital Twins’, granular virtual copies of parts in the manufacturing process, which are enabled by deep learning and artificial intelligence. These models of physical assets deploy internet connected sensors, giving a representation of their physical counterpart’s current status, working condition and functionality to help understand the health and readiness of these parts. By creating ‘Digital Twins’, insights can be garnered to address the tiniest of issues that would otherwise be missed during a manual inspection process.

Another way in which AI and machine learning can help the automotive industry is by analysing the flood of manufacturing data received by machines. By analysing this data thoroughly and looking for anomalies via machine learning, you are able to predict catastrophic failures earlier, avoiding total breakdown and saving businesses large amounts of revenue and brand equity.

By employing machine learning properly, businesses can prevent costly and reputation damaging recalls. This in turn minimises the need for businesses to issue recalls routinely, or for consumers to suffer the potentially dangerous fallout from faulty equipment.

Courtesy of HuffPost UK